We are going to do the job with you as part of the group to don't just present thorough good quality knowledge, but will also timely and helpful solutions to any issues which you face.

Sterility testing should be done on last container materials or other appropriate materials as outlined inside the authorized biologics license software or complement and as described in this segment, except as follows:

By continuing to talk to “Why?” up to five moments, you could dig further and deeper into the issue, going past the plain indicators to determine the basic cause of the failure.

Along with the failure manner and facts in hand, the team can then do the job to determine the root bring about or brings about of the challenge.

When conducting a root trigger failure analysis (RCFA), some several impressive methodologies and methods can be leveraged to uncover the fundamental triggers of failures. Permit’s examine several of the most commonly applied RCFA equipment:

___________________________________________

This cookie is about by LinkedIn and is accustomed to retail store the language preferences of the consumer to provide up content material in that stored language another time consumer go to the website.

Witness statements may be precious for reconstructing the probable sequence of events and consequently the chain of bring about and influence. Human factors can be assessed when the reason for the failure is determined. There are numerous practical ways to protect against merchandise failures occurring in the first place, together with failure method and consequences analysis (FMEA) and fault tree Evaluation (FTA), procedures that may be employed all through prototyping to analyze failures just before an item is promoted.

Comparative summary of compendial USP and automatic blood culture systems for sterility testing of biopharmaceutical goods

Scanning Electron Microscopy which happens to be the scanning from the cracked surfaces beneath substantial magnification to get a better idea of here the fracture. The full fracture transpired following the rod couldn’t hold underneath load once the crack arrived at a important dimension.[three]

) reveals that the sterilization process is outside the business's tolerance for operating or overall performance parameters: Identify whether the nonconformances have been managed properly; and

Good quality by Design to the Pharmaceutical Sector The thought of High quality by Layout (QbD) isn't a whole new strategy but it's only lately that it's been viewed as for all components of the event process for pharmaceutical solutions

Failure Assessment will be the process of gathering and examining data to determine the reason for a failure, generally Using the objective click here of identifying corrective actions or legal responsibility.

The situation on the gaskets in the sterile holding vessel is an important element which can contribute to prospective failures. Common inspection of gaskets Employed in sterile holding vessels and SIP skids is critical to guarantee they provide the airtight seal and move the leak test (see Figure 1).

Edward Furlong Then & Now!

Edward Furlong Then & Now! Anthony Michael Hall Then & Now!

Anthony Michael Hall Then & Now! Keshia Knight Pulliam Then & Now!

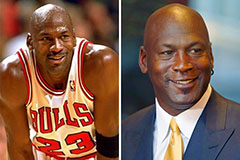

Keshia Knight Pulliam Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now!